Stimulation

-

Surfactants

The modern petroleum industry relies on water-based stimulation fluids to be injected to “free” up trapped oil/gas and move them out from underground reservoir formations to the production wells. Surfactants are “surface-active” chemicals that contain at least two functional groups: one is water-soluble component and another one is water-insoluble (oil-soluble) component.

Typically a surfactant is added to the well stimulation make-up water in order to alter the interaction of this injected fluid in a favorable manner with the oil, gas, and rock interfaces within the treated reservoir. For example, surfactants can increase the interaction between the water and oil by decreasing the oil-water interfacial tension (IFT), reduce the interfacial energy between the water and hydrocarbon gas by lowering the surface tension, and increasing the wetting of the reservoir rock surfaces by the surfactant containing water phase.

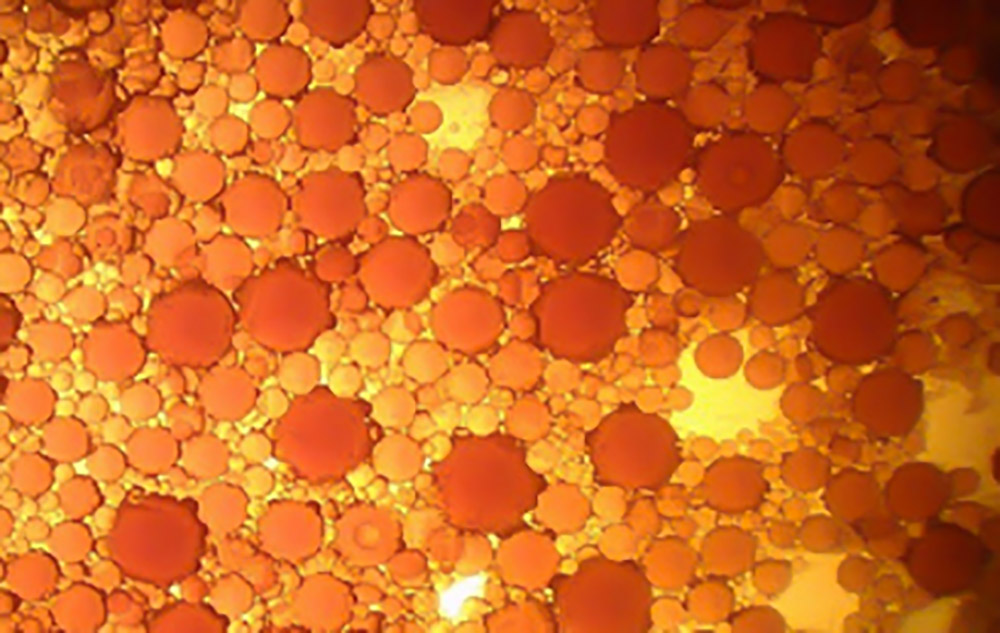

Photomicrograph of

Photomicrograph of

oil-in-water emulsion.Product Line

IOR SURFACTANTS

Surfactant additives in stimulation fluids for improved hydrocarbon recovery.

NON-EMULSIFIERS

Increases oil-water separation of fracturing fluids from well stimulation. -

Friction Reducers

Friction reducers are typically high molecular weight polymers (5 to 30 million Dalton) that will uncoil when added in the aqueous solution to significant decrease pumping pressure losses in hydraulic fracturing operations. The most common friction reducers used in the energy production industry are based on anionic polyacrylamide or other copolymers of polyacrylamide combined with different monomers. A friction reducer can be in liquid form (either in an oil-based emulsion or in a water-based suspension) or in dry-powder form. Once added to stimulation fluids, rapid inversion and hydration is necessary for optimal field performance.

Our product line includes friction reducers that hydrate very quickly and so may be added successfully ‘on-the-fly’. Prior to use, detailed compatibility tests of the selected friction reducer with other additives in the stimulation fluid and brine compositions are recommended. Our laboratories routinely carry out these tests.

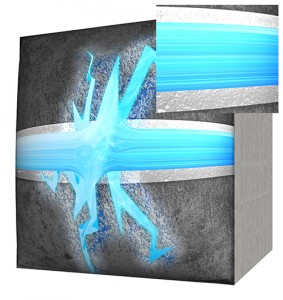

Laminar Like Flow

Increased flow rate due to ChemEOR friction reducer additive – deeper, better fractures

Turbulent Like Flow

Reduced flow rate due to having no friction reducer additive – shorter, poorer fractures

Product Line

EMULSION FR

Reliable, proven liquid-based emulsion friction reducer.

DRY FR

Fast-hydrating, high-performance dry friction reducer with broad salinity range. -

Gelling Agents

Gelling Agents are used to increase the viscoelasticity and/or carrying capacity of proppant for a fracturing fluid. These products are usually synthetic water soluble polymers in their nature. Each polymeric products has been specifically designed to perform in different dosage window with respect to dissolved monovalent and divalent salts presented in each particular treatment fluids.

Depending on application, customer capability and type of treatment fluids, various products will be offer; different chemistries; cationic or anionic and zwitterionic in both liquid form (emulsion or slurry) and solid powder. All of these polymers and chemistries can be used in linear gel system in slick-water and high viscosity friction reducer for low to medium proppant loading or rapidly moving fluid design where velocity provides the bulk of proppant transport. Each gel system has a unique rheological profile which will also help with product selection.

Product Line

CMC

Polymeric carbohydrates such as CMC to boost proppant carrying capacity of fluids and is easily cross-linked while leaving less residue.

SYNTHETIC GELS

Special polymers with controllable gelling functions. -

CLAY STABILIZERS

Depending on the need of a well stimulation operation, a number of special fluid additive compounds are included in stimulation/fracturing fluids to improve efficiency and to reduce the risk of formation damage.

Additives that are commonly used include: clay stabilizers to prevent the clay swelling or migrating by the water-based stimulation fluids, biocides to suppress growth of undesirable bacterial, scale inhibitors to prevent or slow build-up of water-borne scales, and corrosion inhibitors and iron control agents to extend lifetime of pipelines, etc. ChemEOR has developed a series of high-performance additives to meet the demands of our customers.

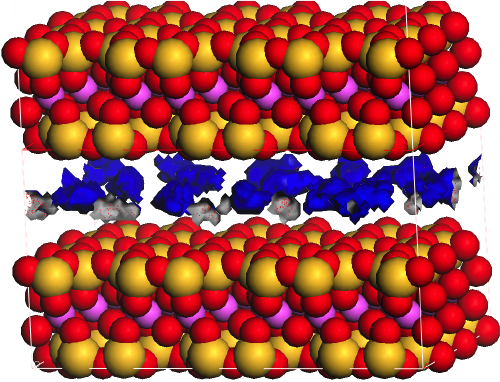

Temporary Clay Stabilizer prevents collapse of layered clays during hydraulic fractures.

Temporary Clay Stabilizer prevents collapse of layered clays during hydraulic fractures.Product Line

TEMPORARY CLAY CONTROL

Inorganic environmentally-friendly clay stabilizer additive in stimulation/fracturing fluids where clay control is required.

PERMANENT CLAY CONTROL